Automotive, Carpentry, Cosmetology, HVAC, Welding, Robotics, Digital Fabrication, and more

Replace outdated tools, reconfigure layouts, integrate new technology, improve safety and workflow

Every decision starts with your curriculum and space

Equipment arrives, is set up, tested, and verified for use

Clear training and simple guides for your team

Your shop should directly support the skills and certifications your students are working toward. We align layouts, tools, and technology with program outcomes—whether that’s machining/CNC, welding, automotive service, construction trades, or digital fabrication—so every piece of equipment serves a purpose in preparing students for their careers.

We start with a conversation about your goals, space, and budget.

Practical designs and right-sized equipment lists.

We handle vendor communication and scheduling.

On-site setup, safety checks, and operational testing.

Walkthrough, basic instruction, and organized documentation.

I know these classrooms because I’ve been on every side of them: as a vocational student, as the installer bringing in new tools, and as the service manager fixing them when they broke. That perspective gives me a rare 360° view of what makes a shop succeed—or fail.

I’ve seen schools spend tens of thousands—sometimes hundreds of thousands—on equipment that never fit the program. That’s wasted money and lost learning time.

LabBuilt Learning exists to make sure every investment translates into real, hands-on skills. We partner with instructors to choose the right equipment, design practical layouts, and ensure everyone feels confident from day one. For me, this isn’t just business—it’s personal.

Graduate of Northeast Metro Tech’s Drafting program, where early mentors sparked a passion for hands-on technical learning.

Lantos Technologies (3D modeling), AET Labs (Service Manager installing and training across dozens of programs), Lovely Earth Gardening (business operations and leadership).

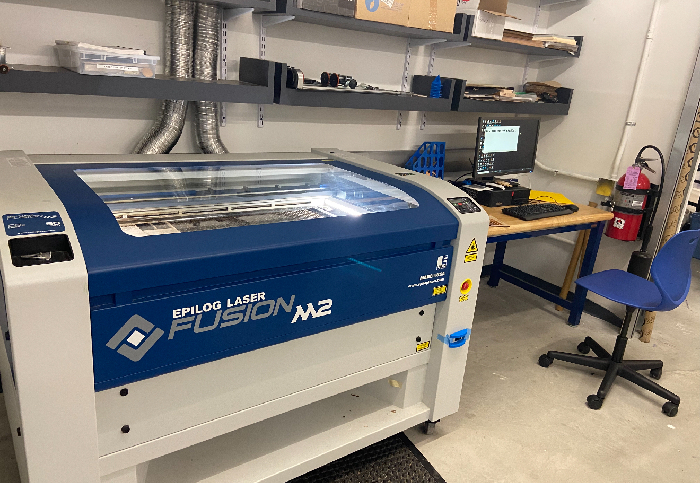

Trained on CNC (Techno), 3D printing (Stratasys, Formlabs, Desktop Metal), laser cutters (Epilog), and advanced scanning (Aura 3D Ear Scanner). Skilled in shop design, installation, maintenance, diagnostics, software setup, and instructor training.